Smart components save weight and increase efficiency

The weight of a trailer has a major effect on its carbon footprint. Lighter materials therefore offer many advantages: The payload is increased, energy consumption is reduced – which saves CO2 and costs.

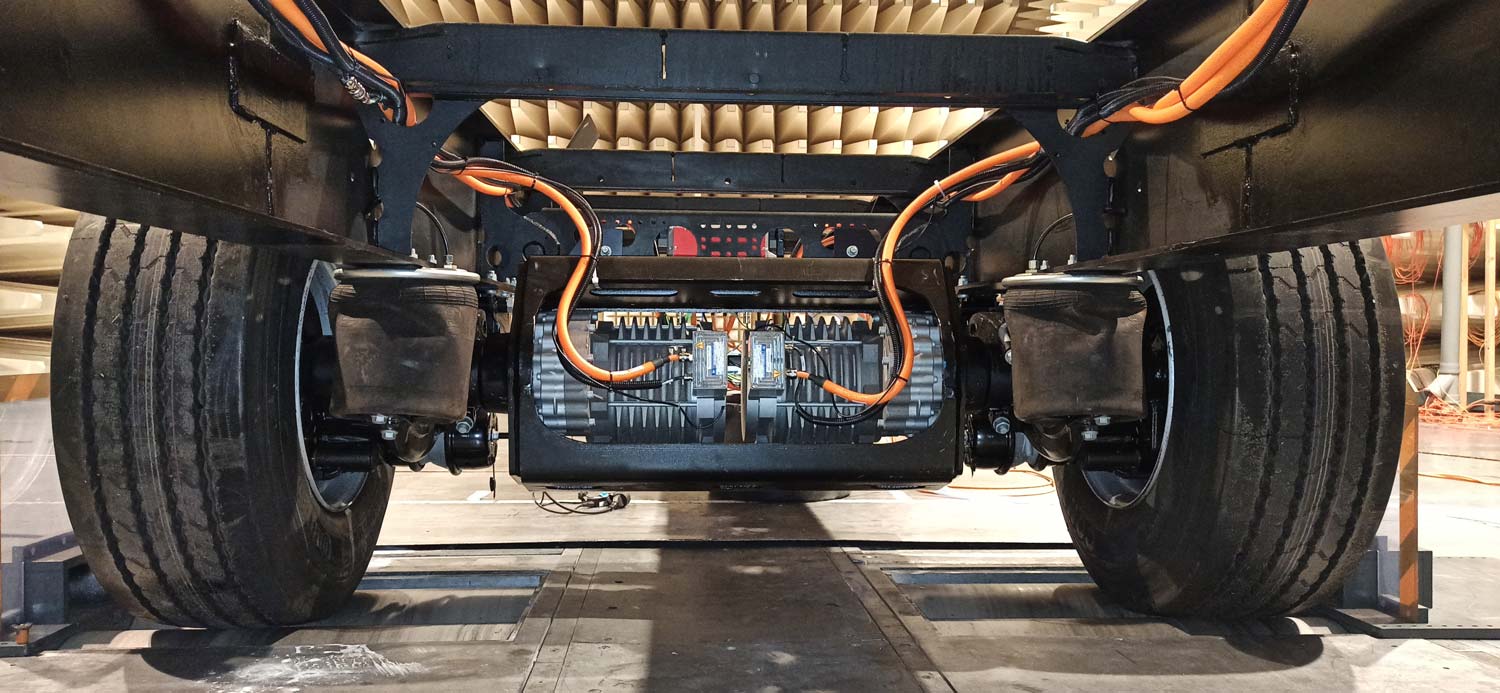

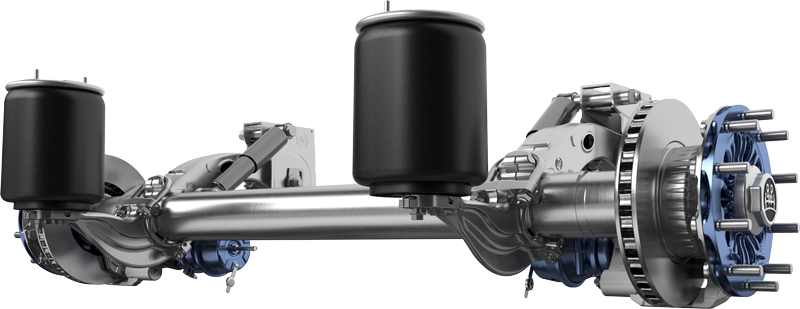

BPW optimises products accordingly and designs components to be lighter, but at the same time robust and durable. For example, the company offers an extra-light aluminium hub for lightweight trailers and especially for tankers and silo vehicles. The forged component saves a whole 54 kilograms of weight in the three-axle unit. This means, for example, that about 64 litres more can be added to a heating oil transport. Another example: the robust trailer running gear ECO Air, which can be used for both on-road and light off-road applications, reduces the weight of the three-axle unit by 27 kilograms.

When driving unloaded or when the vehicle is only partially loaded, the lower vehicle weight also reduces fuel consumption. If the additional payload is utilised, this saves journeys, the environment is protected and CO2 emissions are reduced.

Use data – increase efficiency

Good load securing is also essential for the safety of transports. It can save lives: According to estimates, 20 to 25 percent of accidents in heavy goods transport are caused by loads that have not been secured or have not been secured sufficiently. With the BPW iGurt, load securing is much easier: a sensor is fastened to the tensioning strap with this smart tool, which continuously measures the pre-tensioning force and displays it on the housing. The data gathered is sent to a smartphone app for the driver – he thus can see immediately if there is a deviation and can react accordingly. The iGurt and the app are intuitive to use and can also be networked with telematics systems in the future. Haulage companies can thus also check and document the load securing in their vehicles remotely. In the future, the technology could even enable load securing checks to be done remotely.

Raw materials of the highest quality

Quality begins with the raw materials, preliminary products and components of a product: to ensure that they are of the highest quality, BPW concludes extensive agreements with suppliers. These undertake to protect employees and the environment, to comply with laws on chemicals and hazardous substances, and to ensure the safety of machinery. In addition, BPW expects these partners to continually expand and improve their commitment to environmental protection – for example, in conformity with DIN ISO 14001 and/or Regulation (EC) No. 1221/2009 of the European Parliament and of the Council (EMAS).

The suppliers with whom BPW works are also committed to the RoHS EC Directives and the REACH Regulation. The ROHS Directive restricts the use of certain hazardous substances in electrical and electronic equipment. The REACH regulation stands for the registration, evaluation, authorisation and restriction of chemicals in the EU

In 2019, BPW additionally extended its supplier contracts and conditions of purchase by child rights/child labour. Suppliers thus pledge theirself to recognise the rights of children in the performance of their services and to refrain from child labour.

Own audit concept ensures quality

With its own audit concept, BPW ensures that all suppliers work according to defined criteria. Since 2019, this quality assurance measure has also taken into account topics such as occupational safety and child labour. The company’s supply chain management conducts the audits at set regular intervals.

“Our suppliers should share our values. For us, it is therefore crucial for a cooperation that they commit to sustainability and implement concrete measures to ensure that occupational safety is guaranteed and that the ban on child labour is observed.”

Certification according to automotive standards

Reuse pallets and packaging

In the case of pallets and wood, the company is making increasing use of used pallets: these are obtained from organised waste disposal companies or reprocessed via suppliers.

Disposable packaging and supplier packaging that is returned to BPW by customers is sorted internally and put to new use wherever possible. This is also the practice at other companies in the BPW Group, such as M. Busch GmbH & Co. KG, BPW Hungária and F. Hesterberg & Söhne GmbH & Co. KG.